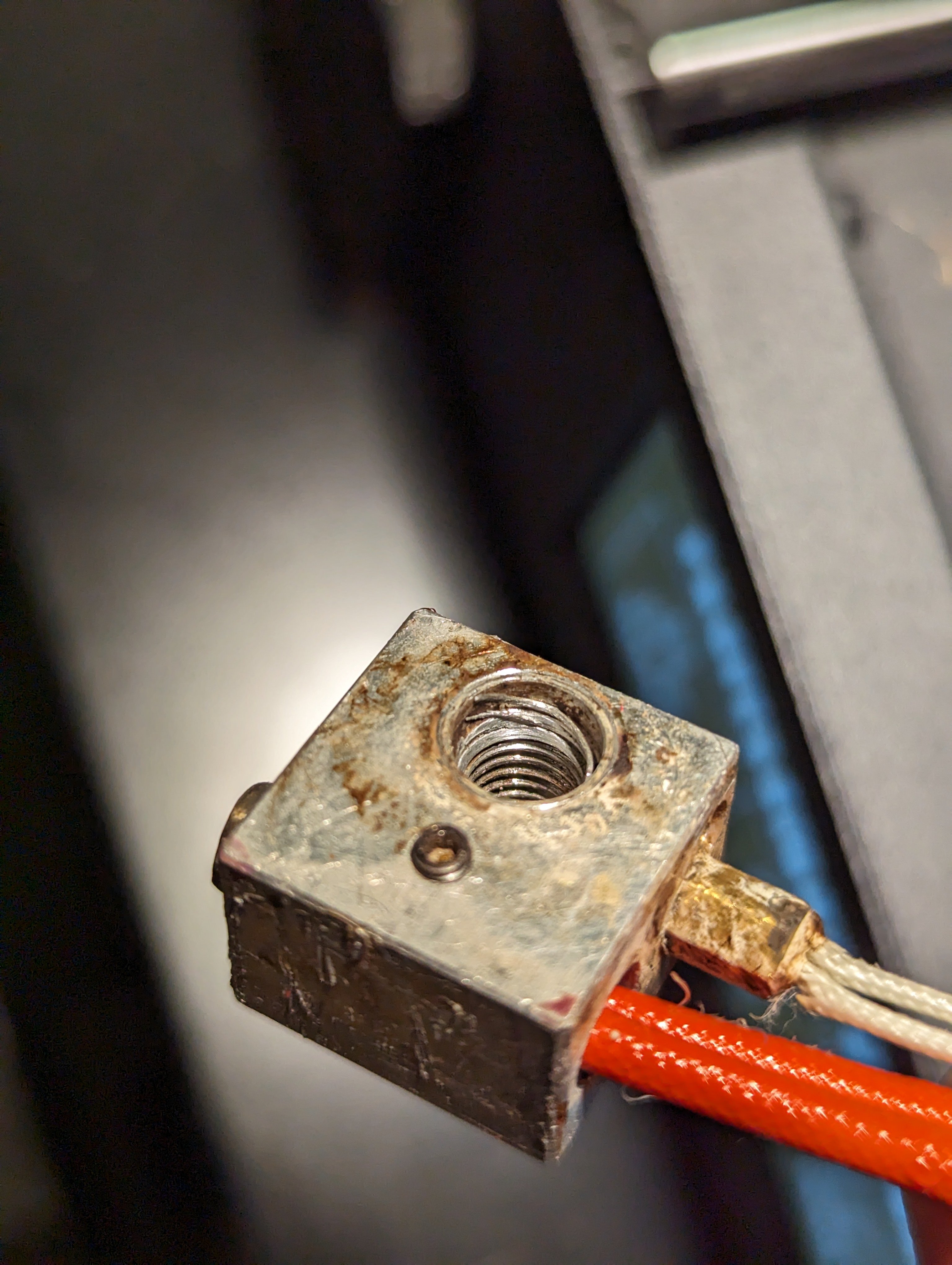

From the pic it looks like cross threading rather than over tightening. Always makes sure it threads smooth before you start tightening

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

It felt like it was in there fine to me, but maybe not.

maybe it's hotend upgrade time then

I have a socket and extension I keep by the printer which fits the nozzle. That way I can screw it in by hand while hot, still easily feel if something is binding, and I don't even have to burn off my fingertips.

Good idea, I'll give that a go.

Been there before. Thankfully, replacement blocks are pretty cheap.

Yeah, I've already spent like $60 trying to help a guy save $10. What's another $20 on the pile? Lol.

Did the same with Trianglelab Dragon. Damaged the heatbreak as well when disassembling the hotend. Now I own a 1.8Nm torque wrench..