Ringing and ghosting usually indicate a vibration or movement issue. Have you checked the rollers, belts and all of those things on your X and Y axis and that they are tight? (but also not too tight)

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

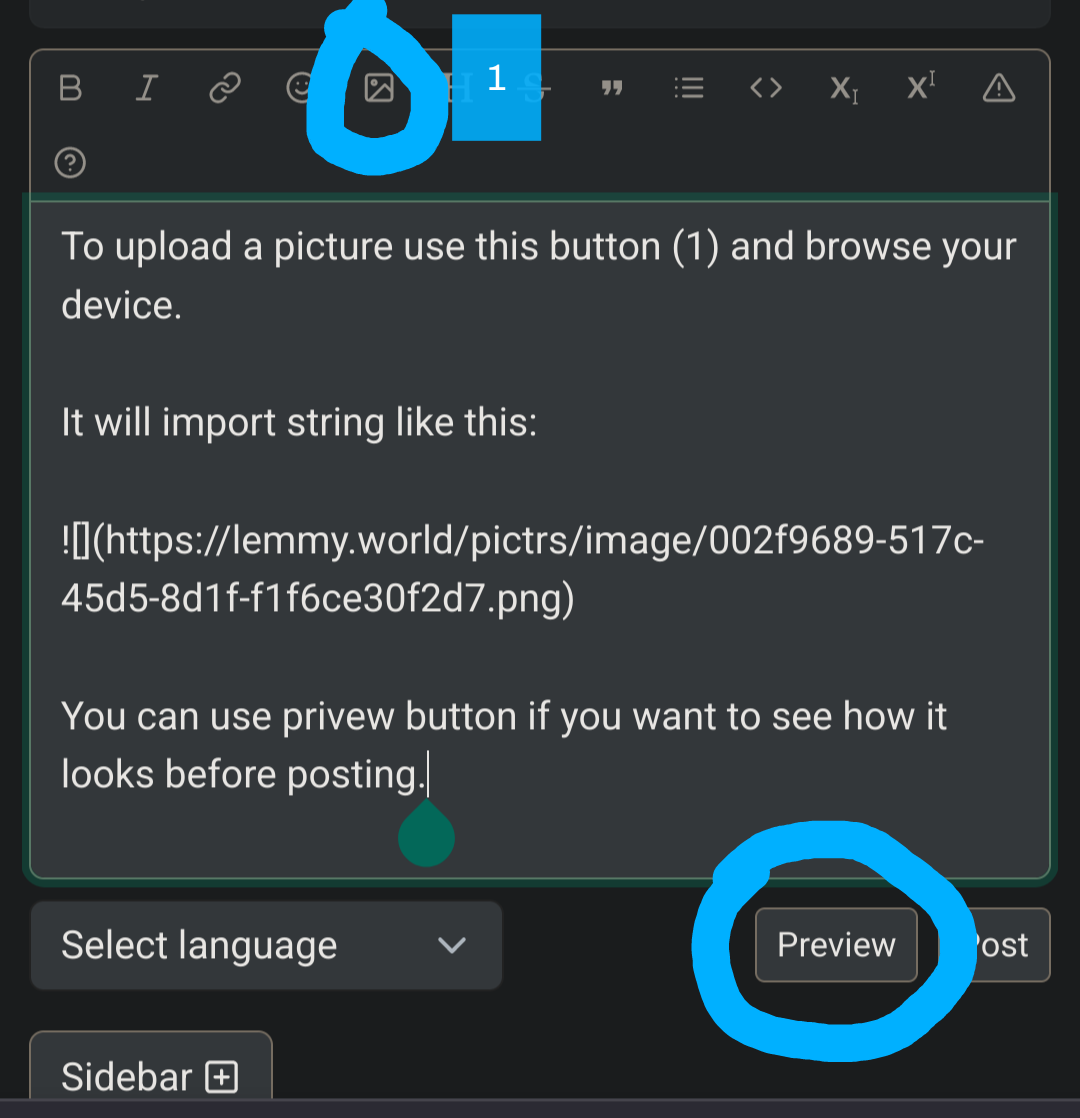

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

I checked the rollers, didn't do that before and i'm running a test print atm. I had already checked the belts.

So, that test print...looks like goop in the shape of the object i tried to print. For some reason the printbed is also way too high now, the first 2 layers basically merged into the third. I'm back to square one it seems.

Much easier with a picture

But in general hardware is first thing to check and make sure its working fine. Then PID tune your bed and hotend, calibrate your temp, flow, retraction. Then if you are using klipper you can do ringing compensation and pressure advance. At this point the problem should be far away behind you

If you made any chanes on your hotend (I guess you did) you should definitely PID tune it

I'm still messing with the printer and after a lot of struggling it went from printing horrible looking to printing spaghetti back to printing something that looks somewhat melty. The hotend itself is still stock, but i just found out i don't have a way to connect the printer to my pc.

After all this time it seems like the printer jumbled a lot of settings for no apparent reason, including something that controls the temperature. I printed a temp tower and the screen showed the temp actually changed but the result is identical for each temp.

Temp tower can look like that if filament can tolerate huge temp range, like a lot of good pla. You can just pick some temp in the middle of manufacturers recomendation. I actually print single wall hollow cube as tower and looking for best surface and strength by sepparating it with fingers. I do the same for flow, but also measurimg wall thickness.

Stock hotend is not best, but probably not limiting you unless you are trying to print rly fast. As long as it doesnt leak or clog and if thermistor and heater are seated properly and fan is spinning you shouldnt need an upgrade.

You can connect printer with usbA to usbB cable i guess. But your issues are diferent now, its best to make a post with pictures this time. Its too much guessing like this

Yeah it's nearly impossible without any visible cues, i still haven't been able to upload photo's yet. Not even ones as small as 900kb

It gives me: cannot be converted something about JSONObject.

...huh, it does work with the screenshot i took.

...huh, it does work with the screenshot i took.

Yeah its pain sometimes, but using browser usually works

I've decided to do a complete set up of everything in hopes that it will work again afterwards. I'll recalibrate the extruder and set up a new temp tower and all that good stuff.