Curious what symptoms you have when the wheels start wearing out? I've got quite a few hours on my printer and haven't touched the wheels after replacing them when it was new because of shipping damage. Never even considered that they could wear out (apart from the bearings).

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

The wheel surfaces themselves tend to wear out and cause eventual slop due to being soft material. This is most evident in the Y axis which not only travels in a different orientation than X and Z, but also bears a lot of weight. This of course causes intermittent sag in Y. I've gone through several sets of bed wheels between 3 E3P's so far. I'm converting them all to linear to reduce the amount of maintenance and increase precision and accuracy.

Slop in wheels usually manifests as what one diagnoses as intermittent underextrusion or a funky extruder drive that might be skipping. It technically is underextrusion, but it's not because the printer is out of calibration, it's because a section of the bed now has variable Z due to an issue in Y that is usually overlooked.

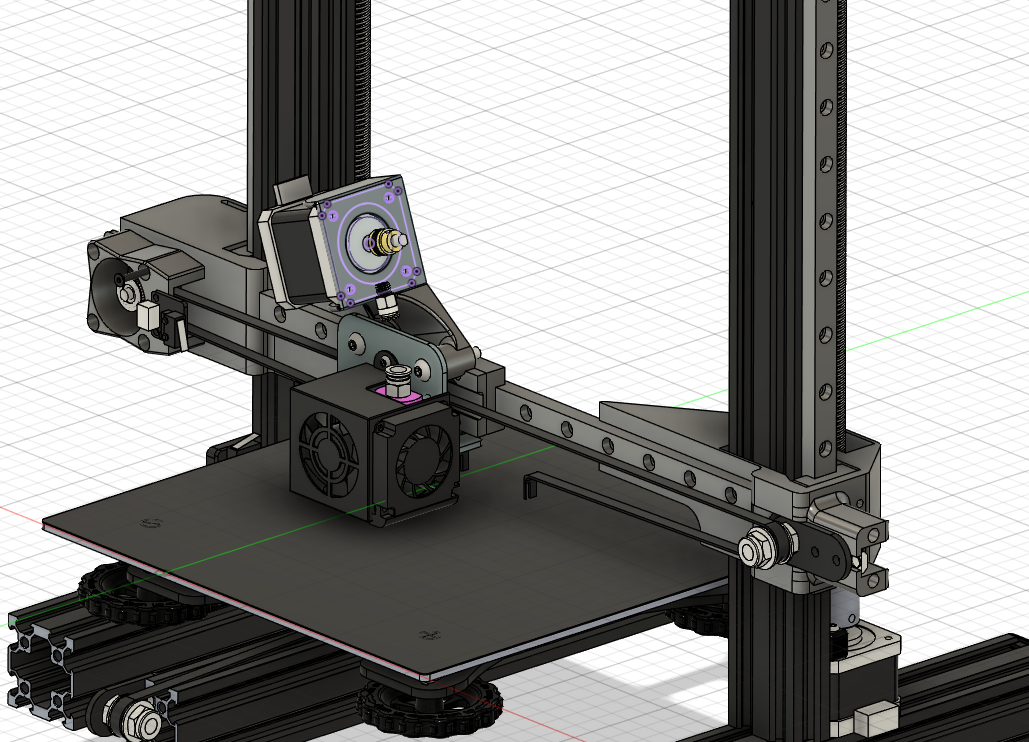

I'm really pleased with the print quality coming out of the proto, and I haven't even swapped in the upgrade hotend yet.

I've also made a bunch of structural and aesthetic improvements to minimize print struggles with the proto parts, increase strength, tweaked a few things, and added a few nice-to-haves.

Wow looks great! Thanks for sharing.

Thanks, and you are very welcome! It will get published for everyone once it is refined enough. I wanted a full linear ender but nearly all of the rail kits lose offset, add weight, and are generally kludgey. This is light, fast, cheap, and reuses most of the original hardware. It also ditches the X gantry bar and most of of the motion brackets.

By rail kits, you mean stuff you find on amazon/aliexpress? "Upgrades" you find there tend to be poorly designed and often very low quality unfortunately.

If you want some inspiration, check out Churls' linear rail mod. I think he's a well respected modder within the Annex community so his design ought to be well thought through.

By rail kits, you mean stuff you find on amazon/aliexpress? “Upgrades” you find there tend to be poorly designed and often very low quality unfortunately.

If you want some inspiration, check out Churls’ linear rail mod. I think he’s a well respected modder within the Annex community so his design ought to be well thought through.

Wow, how kind of you to come by and assume my hardware is shit, that I'm not a respectable modder or that I don't have worthwhile design experience, while telling me to stop what I'm doing and use someone else's design. Get lost.

Overreaction much

I don't need someone shitting all over my work, especially when I'm about to give it away as a gesture of kindness to the community.

Do you really want to encourage, or at least enable that sort of behavior? I'm here for positivity. They can, and should, get lost.

You can't read, he agreed with you and called the kits you had problems with trash. And then tried to help you by guiding you to a project similar to yours to use as inspiration.

If you're here for the positivity, I'm surprised you're bringing so little yourself.

It reads as criticism of using inexpensive linear rails, and my work, and my skills. I'm being told to go get my ideas from someone else. Nothing there is positive from my point of view.

This is not worth arguing about and makes me regret posting my work here or sharing my work with the community.

I'm actually making the swap to full linear too. I have the Ender Extender XL kit, and I'm not loving the way the rollers work with it. I printed a dual Z setup but it's been fiddly. I'm hoping that the linear setup will get me where I want to be.