this post was submitted on 07 Jun 2024

748 points (97.2% liked)

Greentext

4392 readers

1381 users here now

This is a place to share greentexts and witness the confounding life of Anon. If you're new to the Greentext community, think of it as a sort of zoo with Anon as the main attraction.

Be warned:

- Anon is often crazy.

- Anon is often depressed.

- Anon frequently shares thoughts that are immature, offensive, or incomprehensible.

If you find yourself getting angry (or god forbid, agreeing) with something Anon has said, you might be doing it wrong.

founded 1 year ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

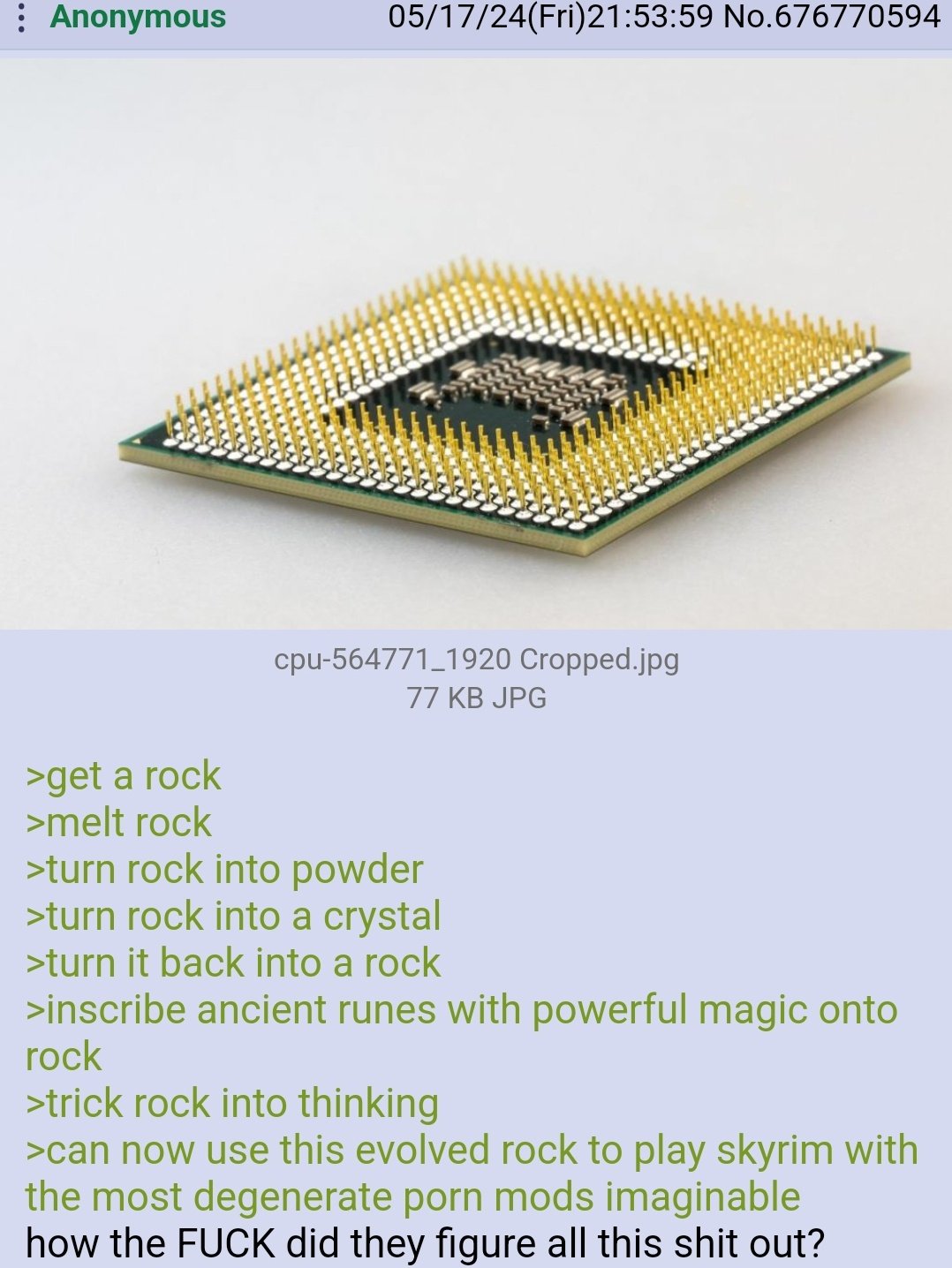

You start with macroscopic photolithography, add material science of semiconductors and then iterate a million times. It didn't start at nanoscale.

Give me a break... I'm still trying to wrap my head around how transistors work. For a layman this is like magic.

Photolithography started as a printing technique and is pretty basic.

It's essentially the same as somebody with a couple of cans of spray piant and a handfull of carboard sheets with cutouts spray paimting a muti-color tag on a wall.

As the logo kept getting smaller and smaller and the errors of the process of just putting that cardboard in front of the wall and spraying the whole thing had too much imperfection for tiny logos, they had to come up with more and more tricks to get it to still do tiny logos without those logos ending up too distorted.

Like glueing a cardboard to the wall and then dissolving it after spraying :)

Exactly, and “we need this as small and precise as possible” means “can lasers do it?” As an engineer I default to fast and precise means computer guided laser if possible

They use electron beams and extreme UV light nowadays. Lasers are not necessarily the best light source, even at other wavelengths.