Lemmy Shitpost

Welcome to Lemmy Shitpost. Here you can shitpost to your hearts content.

Anything and everything goes. Memes, Jokes, Vents and Banter. Though we still have to comply with lemmy.world instance rules. So behave!

Rules:

1. Be Respectful

Refrain from using harmful language pertaining to a protected characteristic: e.g. race, gender, sexuality, disability or religion.

Refrain from being argumentative when responding or commenting to posts/replies. Personal attacks are not welcome here.

...

2. No Illegal Content

Content that violates the law. Any post/comment found to be in breach of common law will be removed and given to the authorities if required.

That means:

-No promoting violence/threats against any individuals

-No CSA content or Revenge Porn

-No sharing private/personal information (Doxxing)

...

3. No Spam

Posting the same post, no matter the intent is against the rules.

-If you have posted content, please refrain from re-posting said content within this community.

-Do not spam posts with intent to harass, annoy, bully, advertise, scam or harm this community.

-No posting Scams/Advertisements/Phishing Links/IP Grabbers

-No Bots, Bots will be banned from the community.

...

4. No Porn/Explicit

Content

-Do not post explicit content. Lemmy.World is not the instance for NSFW content.

-Do not post Gore or Shock Content.

...

5. No Enciting Harassment,

Brigading, Doxxing or Witch Hunts

-Do not Brigade other Communities

-No calls to action against other communities/users within Lemmy or outside of Lemmy.

-No Witch Hunts against users/communities.

-No content that harasses members within or outside of the community.

...

6. NSFW should be behind NSFW tags.

-Content that is NSFW should be behind NSFW tags.

-Content that might be distressing should be kept behind NSFW tags.

...

If you see content that is a breach of the rules, please flag and report the comment and a moderator will take action where they can.

Also check out:

Partnered Communities:

1.Memes

10.LinuxMemes (Linux themed memes)

Reach out to

All communities included on the sidebar are to be made in compliance with the instance rules. Striker

view the rest of the comments

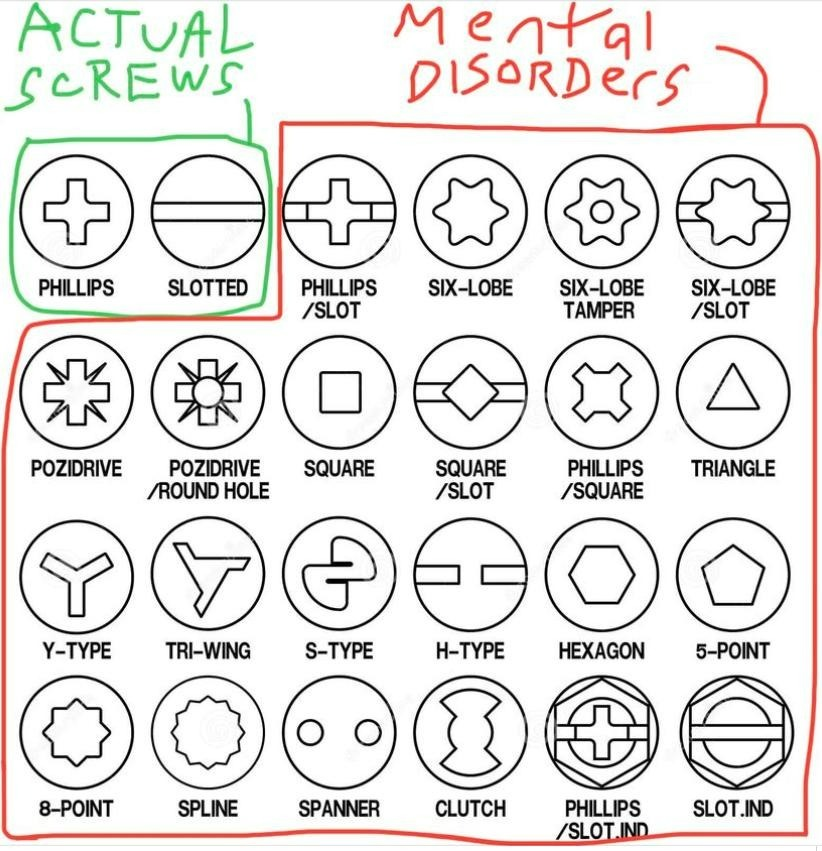

Honestly, I dont understand why everything isnt square drive.

its simple, and its a pretty strong design that resists camming out and rounding off.

Some claim to have stripped Robertson screws but to be fair, the metal used and amount of torque the peson applies is the biggest reason for problems.

Phillips heads were supposed to solve the over torquing problem, but everyone didn't listen to standard specifications and didn't bother using them as they were meant to be made and used. The Philips head was supposed to slip once the correct torque was applied. Unfortunately, this positive benefit became a negative. With poor metals and a mismatched driver bit to screw head along with not using the screw head that was meant for the specified torque demands, the Phillips screw became known for stripping.

Trying to implement non overtorquing feature to the square bit and you will find how similar it will look to the Phillips head.

Right now, Torx is the best at not stripping, but good luck if the screw is overtorqued. Eventually, the cheap metal gives out with the screw head, or bit, snapping off.

This is a common misconception. Phillips was not supposed to solve over torquing. It was designed to allow higher torques, stop slipping and self centre. It was only really good at self centering.

A screw designed to stop it being over toqured is a terrible idea. The screw should be smaller to prevent if higher torque is needed. If over torque is an issue then reducing the power to the driver is a much better solutio (easily done in industrial setting Phillips was designed for). You can also reduce the size of the screwdriver supplied.